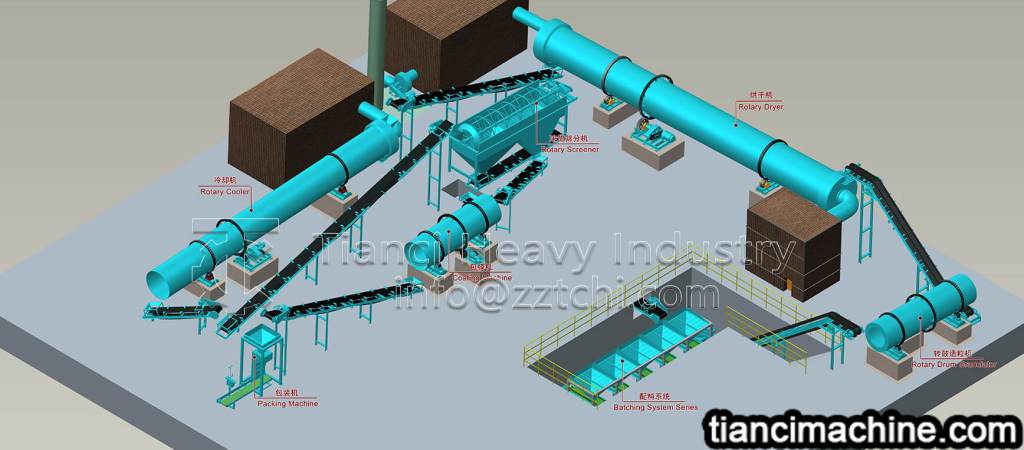

1. Ingredients of raw materials: urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, general calcium), potassium chloride (potassium sulfate) and other raw materials are equipped in a certain proportion (according to market demand and soil test results in different places).

2. Material mixing: mixing the raw materials evenly to improve the uniform fertilizer efficiency of the whole fertilizer granule.

3. Material granulation: Feed the uniformly stirred material into the fertilizer granulator for granulation (drum granulator or extrusion granulator can be used).

4. Particle drying: The granulator is fed into the dryer, and the moisture contained in the granule is dried to increase the strength of the granule and to facilitate its preservation.

5. Particle cooling: After drying, the temperature of fertilizer particles is too high and easy to agglomerate. After cooling, it is easy to store and transport in bags.

6. Particle Classification: After cooling, the particles are classified. The unqualified particles are crushed and re-granulated, and the qualified products are screened out.

7. Finished film: coat qualified products to increase the brightness and roundness of particles.

8. Packaging of finished products: Film-coated particles, i.e. finished products, are packed and stored in a ventilated place.