- The low noise of the equipment makes its operation safer and more reliable.

- Organic fertilizer particles are smoother, more moderate hardness and higher moulding rate.

- It can be applied to the production demand of different materials and particle diameters.

- The particles are uniform in composition, neat in shape, smooth in surface and dense in density, which is convenient for storage and transportation.

- Organic fertilizer equipment can process spherical fertilizer, powdery fertilizer and cylindrical granules. There is no need to add any binder to the granulation of the counter-roll extrusion granulator.

Organic fertilizer processing equipment can be used in large, medium and small scale organic fertilizer production lines. Organic fertilizer raw materials can be all kinds of animal manure, straw plant crude fiber, domestic waste, industrial and agricultural waste, etc.

作者: machine tianci

How to Find Good Organic Fertilizer Equipment

Organic fertilizer equipment is a kind of equipment which uses chicken and pig droppings as the main raw material, adding a certain amount of nitrogen fertilizer, phosphate fertilizer, potassium fertilizer, potassium sulfate, ferrous sulfate and other substances, and takes rice bran, yeast, soybean meal and sugar for a certain period of time as a biological bacterium, and produces a bio chemical fertilizer by mixed fermentation under the action of sulfuric acid.

Which good organic fertilizer equipment, I recommend Zhengzhou Huaqiang Heavy Engineering Technology Co., Ltd. to you, we only want to continuously improve the quality, the price is unchanged, the ratio of goods to three, not the best, as long as you trust.

In the market, there are two kinds of phenomena:

1. Customers only pay attention to the quality of organic fertilizer and ignore the price, which often results in high cost, a lot more money than others, and a longer cycle of cost recovery.

2. Paying more attention to price and neglecting quality technology often leads to loss and loss. Organic fertilizer production equipment plays a limited role in production and often presents various problems.

No matter what kind of situation is a loss for enterprises, how to avoid it is a comprehensive process. Enterprises or consumers need to be measured in many ways and angles.

Organic fertilizer production process is the first factor to consider. No one wants to buy the equipment when a pile of scrap iron, money spent, but the value is 0, organic fertilizer production equipment and compound fertilizer production equipment is very different, compound fertilizer equipment is mainly the production process is simpler, organic fertilizer needs drying, granulating, padding, packaging and so on a few large processes. Errors in related processes can affect overall quality.

Secondly, it is very important to choose the manufacturer. In the organic fertilizer industry, the enterprises with high reputation are relatively guaranteed in technology and quality, because the accumulation of reputation needs good reputation. Who will do word-of-mouth marketing for enterprises without advantages? The products produced are uniform in particle size, balanced in nutrients and stable in quality. Moreover, the product formulation is developed by experts according to the soil nutrient status and crop characteristics, after a long-term test. The formulation is reasonable, targeted, nutrient-rich and high content, so it is safe to use.

The budget of input and output, when purchasing organic fertilizer production equipment, needs to arrange how many equipment to purchase and how much to spend according to the production task and development trend of the enterprise. The key to increase agricultural production and income lies in the reduction of agricultural cost. It is very important to select a fertilizer with good quality and reasonable price, otherwise it will not pay off.

In the actual purchase process, we also need to consider the service, after-sales maintenance, technical content, and material aspects to make an integrated comparison, to find their most satisfactory.

Roller granulation production line

Roller granulation production line

Process characteristics:

1. Energy saving and consumption reduction. Extrusion granulation adopts non-drying technology and normal temperature granulation. Compared with other methods, it does not need drying measures such as fuel oil and gas.

2. The investment is low, the drying process is omitted, and the rate of material return is low, and the process flow is simple.

3. Dry granulation does not require additional additives, but only uses the intermolecular force of the material itself, which not only simplifies the process, but also reduces energy consumption.

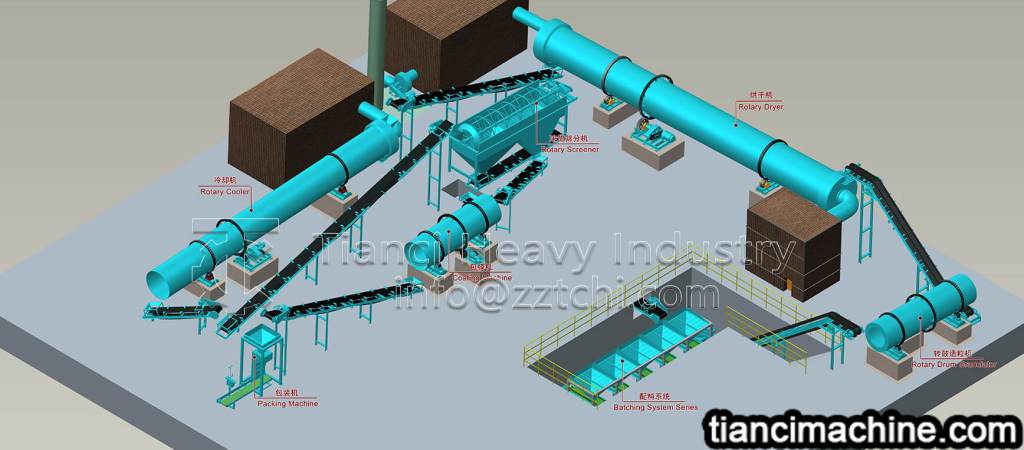

Process Flow of NPK Production Line

1. Ingredients of raw materials: urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, general calcium), potassium chloride (potassium sulfate) and other raw materials are equipped in a certain proportion (according to market demand and soil test results in different places).

2. Material mixing: mixing the raw materials evenly to improve the uniform fertilizer efficiency of the whole fertilizer granule.

3. Material granulation: Feed the uniformly stirred material into the fertilizer granulator for granulation (drum granulator or extrusion granulator can be used).

4. Particle drying: The granulator is fed into the dryer, and the moisture contained in the granule is dried to increase the strength of the granule and to facilitate its preservation.

5. Particle cooling: After drying, the temperature of fertilizer particles is too high and easy to agglomerate. After cooling, it is easy to store and transport in bags.

6. Particle Classification: After cooling, the particles are classified. The unqualified particles are crushed and re-granulated, and the qualified products are screened out.

7. Finished film: coat qualified products to increase the brightness and roundness of particles.

8. Packaging of finished products: Film-coated particles, i.e. finished products, are packed and stored in a ventilated place.

Ecological Advocate–Organic Fertilizer Production Process

Advantages of Organic Fertilizer:

1. The nutrient element is more comprehensive, the fertilizer effect is gentle and lasting.

2. It can increase and renew soil organic matter, promote microbial reproduction, enhance respiration, promote root growth, and improve soil physical and chemical properties and biological activity.

3. Reducing environmental pollution is the main nutrient source of green food production.

4. It can improve the quality of agricultural products, such as sweetness, color and so on.Organic Fertilizer Production Process

Organic Fertilizer Equipment:

1.The drum screener machine is a new generation of self-cleaning special equipment after the electric vibration screen and the ordinary mesh drum screener machine produced by major domestic companies.

2.Drum fertilizer dryer is one of the traditional drying equipment, which has reliable operation, high flexibility, strong adaptability and processing capacity.

3. Double axis mixer with two rotating blades relative movement, can be continuously stirred. The mixing blade has good wear resistance and long service life.

4. The packaging machine integrates feeding, weighing, bag clamping, conveying and sewing. It can work continuously, has fast packing speed, and is easy to operate.

Phosphate Fertilizer Production Process

Phosphate fertilizer is made from fish bones, bones, eggshells, freshwater fish scales, cut hair, nails and so on. Phosphate fertilizer can be divided into water-soluble phosphate fertilizer, citric acid-soluble phosphate fertilizer and insoluble phosphate fertilizer according to its solubility. Phosphate fertilizers are classified into wet and hot methods according to production methods.

Problems in Phosphate Fertilizer Absorption:

1.The most direct symptoms of phosphorus deficiency are crop vary in size in the field, especially in orchards. Most fields will also behave like this now. Leaf surface at the top of a plant is small and purple.

2.Zinc fertilizer and phosphorus fertilizer can not be mixed. If zinc fertilizer and phosphorus fertilizer are mixed together, zinc phosphate, which is not easy to dissolve in water, will be formed. Zinc phosphate crop is very difficult to absorb and can not achieve the desired effect.

3.Excessive nutrients such as iron, zinc and nitrogen in soil can inhibit the absorption of phosphorus fertilizer.

4.When the PH value is 5.5, the absorptivity is only about 15% of PH value 6.5.

5.The absorptivity at 13 degrees is only 31% at 21 degrees.

Our company mainly produces a complete set of fertilizer manufacturing equipment. Welcome new and old customers to visit our company and discuss cooperation.

Chain compost turning machine

Chain compost turning machine and organic fertilizer production complement each other. The chain compost turning machine is applied to the aerobic fermentation composting of waste materials such as livestock manure and sludge garbage. At the same time, the chain compost turning machine can satisfy the width of various fermentation tanks, Chain compost turning machine is one of the popular products in our company’s fertilizer turner series. The chain compost turning machine can effectively ferment the bio-organic fertilizer in the organic fertilizer production line, and has the functions of sterilization, water removal and deodorization, and improves the fermentation efficiency. Organic fertilizer is rich in organic matter, which can improve the physical properties of the soil and improve soil nutrients. Therefore, organic fertilizer has significant benefits to society and ecology.

Chain compost turning machine product features

- The chain compost turning machine adopts mechanized running water composed of rail-type strip fermenting tank and walking type automatic turning and throwing machine, which has low energy consumption, easy operation and human saving.

- The fermentation of organic fertilizer does not require external ventilation, sufficient oxygen supply, anaerobic inhibition, and complete control of odor generation.

- The chain compost turning machine is a multi-tooth plate structure conveyor that can be at an angle of 45 degrees to the bottom of the pool.

Other Organic Fertilizer Compost Equipment: Double Screws Compost Turning Machine

Simple Compost Turning Machine Windrow Compost Turning Machine

Chicken Manure Organic Fertilizer Biological Fermentation

Step 1: Mix the starter well. 1-15 tons of dry chicken manure (about 2.5-3.5 tons of fresh chicken manure) plus 1 kg of chicken manure organic fertilizer bio-starter, 5-10 kg of rice bran or corn, bran per kg of starter on average, after stirring evenly, it is withdrawn into the prepared chicken manure, and the effect is the best.

Step 2: Adjust the C/N ratio. The C/N ratio of fermented chicken manure should be kept at 25-30:1, and the acidity-basicity should be adjusted to 6-8 (ph). Because of the high C/N ratio of chicken manure, some straw, straw and mushroom residue should be added to ferment together.

Step 3: Regulate the moisture content of chicken manure. In the process of fermentation of organic fertilizer, it is very important whether the moisture content is suitable or not. It should not be too high or too low. It should be kept at 60%-65%. The method of judging is to grasp a handful of materials tightly, see the watermarks on the fingertips but not drip water, and disperse them on the ground.

Step 4: Build a pile of chicken manure. When making chicken fermentation compost, it can not be too small or too short, which will affect fermentation. The height is generally about 1.5 meters, the width is about 2 meters, and the length of the compost is more than 2-4 meters.

Step 5: Mix well and ventilate. Chicken organic fertilizer bio-starter is an oxygen-consuming microorganism, so oxygen supply measures should be increased in the process of fermentation. Large-scale farms can use organic fertilizer compost machine turning compost, so that mixing, frequent turning and aeration are appropriate, otherwise the effect of material fermentation will be affected by anaerobic fermentation.

Step 6: Fermentation is completed. Generally, after 48 hours of accumulation of chicken manure, the temperature will rise to 50-60 degrees C, and on the third day it can reach 65 degrees C or more. Under this high temperature, it will turn over once. Generally, there will be 2-3 times of high temperature above 65 degrees C in the fermentation process, and the fermentation can be completed by turning over 2-3 times. Normally, the fermentation can be completed within a week or so, so that the material can completely deodorize and ferment. Ripening, sterilization and insecticidal.

Treatment of chicken manure

Chicken manure has the highest nutritional value in all conventional animal manure. Chicken manure contains 28% crude protein, 18% pure protein and 8% total amino acid. The content of this amino acid is very balanced. It is also rich in B vitamins and a variety of trace elements.

Chicken manure is a cheap low-energy protein feed. Replacing part of the protein feed with chicken manure and supplementing some energy feed can greatly improve the economic benefits of animal husbandry and breeding, reduce pollution, purify the environment and form an ecological industry. Similarly, chicken manure can also be fermented into high-quality organic fertilizer to form an organic fertilizer production line, bringing good economic, ecological and social benefits.

Traditional chicken manure accumulation or organic fertilizer biological fermentation method is adopted. The traditional chicken manure fermentation method is to accumulate chicken manure for about 5 to 6 months, which naturally emits odor and decomposes harmful bacteria. The bio-fermentation method of chicken manure organic fertilizer is to use the starter, which can accelerate the fermentation time, and generally can be completed in about 7 days. This fermentation method increase the nutrient composition of chicken manure, has good fertilizer effect, is safe and convenient to use, and is welcomed by users.

Chicken Manure Organic Fertilizer Production Process

1. The main purpose of organic compost machine

The main purpose is to mix organic solid waste with auxiliary materials (plant straw, etc.) and microbial starter with water content less than 60% to fully decompose and sterilize through the pond. Aerobic fermentation for deodorization and dehydration. In Fanguo, the moisture content of the decomposed material is usually 30-35%. After screening, it can be directly used for granulating organic fertilizer or powdered organic fertilizer.

2. Organic fertilizer granulator

After screening the fermented organic matter, the raw materials of other ingredients are metered, compounded and mixed according to the ratio. After thorough mixing, the material is uniformly and continuously fed into the box of the organic fertilizer granulator through a speed belt conveyor. After grinding them into spherical pellets with a rounding machine, they are dried in a low temperature and strong air (<65 C) of the dryer. After cooling and sieving, the finished granules are transported through a bucket elevator to the finished product warehouse and packaged in a computer. Bio-organic fertilizers can be produced by adding functional bacteria, and organic and inorganic fertilizers can be produced by adding phosphorus and potassium (total nutrient content less than 15%).